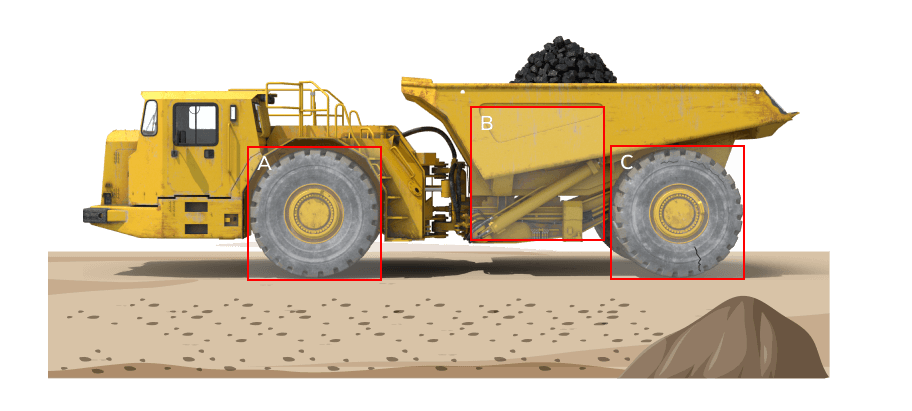

A mining company operates a large fleet of heavy equipment and manages a vast number of tires. This makes it difficult to keep track of tire performance and maintenance schedules. This can lead to downtime, safety incidents, and increased costs for the company.

Introduction

Challenges

Extreme Terrain Conditions: Mining operations takes place in harsh terrains with sharp rocks, and uneven surfaces. It leads to accelerated tire wear and damage.

Premature Tire Wear: Mining vehicles carry enormous payloads. It causes increased stress on tires, which leads to premature wear and failure.

Safety Concerns: Tire failures in mining vehicles can result in serious accidents. It causes significant risks to both equipment operators and other workers on-site.

Operational Downtime: Downtime due to tire issues can be particularly significant in the mining industry, where ongoing operations are critical to achieving production targets.

Costly Replacements: Running replacement tires is a big expense, finding a balance between tire replacement programs, and maintaining tire performance is a challenge.

Challenges

Solution

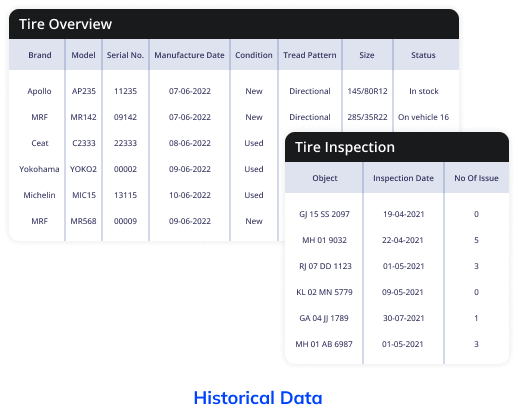

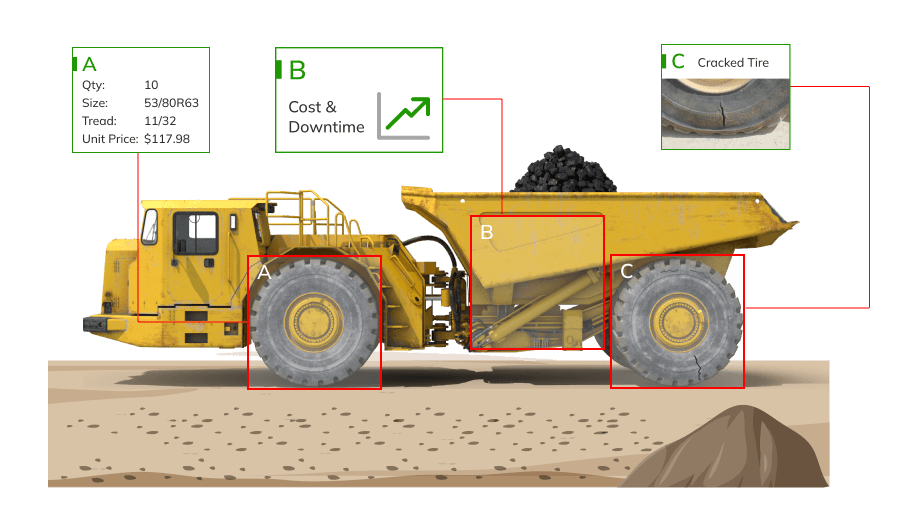

Regular Tire Inspections: The software includes an inspection module that automates routine tire inspections, ensuring proper inspection and reducing the risk of tire damage.

Data-Driven Maintenance: Collecting and analyzing data on tire performance, including tread wear and damage, allows mining companies to optimize maintenance practices and reduce downtime.

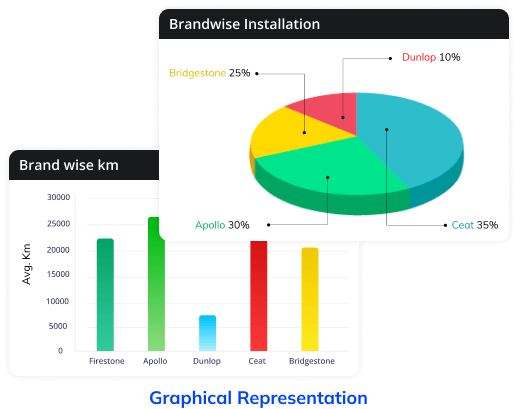

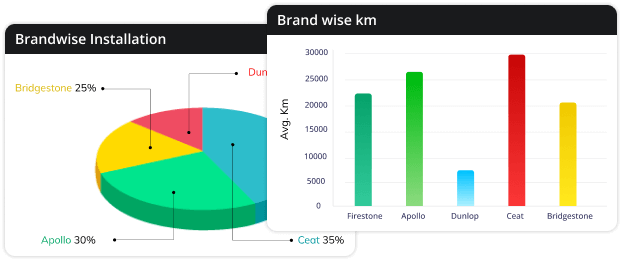

Tire Installation Chart: The software included a brand-wise tire installation chart to track tire installation as per brand on vehicles and ensure that each vehicle was equipped with the right type of tire.

Terrain-Specific Tire Selection: Mining companies can use information from the software to make informed decisions about which tires are best suited for a particular terrain. This also increases tire longevity.

Results

Cost Savings – Mining companies optimize tire usage and maintenance, reducing the need for premature tire replacement and lowering maintenance costs.

Data-driven Decision-making – The software provides insights into tire performance and maintenance needs. This enables more proactive and informed decision-making.