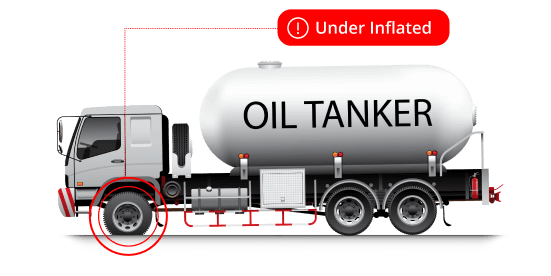

Transporting hazardous chemicals requires adherence to strict safety regulations to protect human health and the environment. One critical aspect of this safety protocol is ensuring that the tires on the vehicles used to transport these chemicals are maintained at the correct pressure levels. Underinflated tires can lead to tire failure, causing accidents, chemical spills, and environmental contamination.

Introduction

Challenges

Hazardous Cargo: Transporting chemicals comes with inherent risks, and any accidents or leaks can have severe consequences for the environment and public safety.

Tire-Related Incidents: Blowouts or tire failures can lead to accidents, spills, and delays, especially when transporting hazardous materials.

Regulatory Compliance: The transportation of hazardous materials is subject to strict safety regulations, including those related to vehicle maintenance and safety.

Challenges

Solution

To address these challenges, adopt our tire pressure monitoring systems

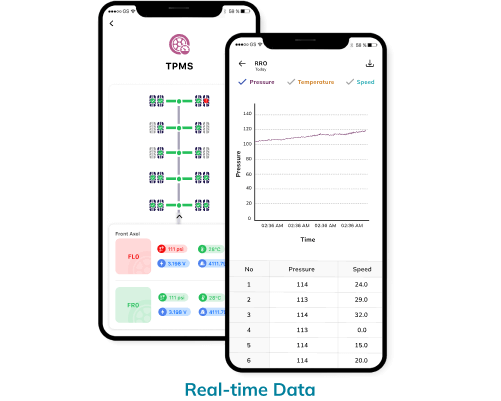

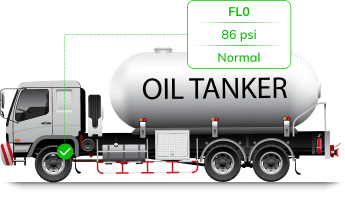

TPMS Sensors: TPMS sensors are installed on each tire of the chemical transport vehicles, constantly monitoring tire pressure and temperature.

Real-Time Data Integration: TPMS data is integrated into the fleet management software, allowing for real-time monitoring and analysis.

Real-Time Monitoring: During transit, the TPMS system continuously monitors tire pressure and temperature.

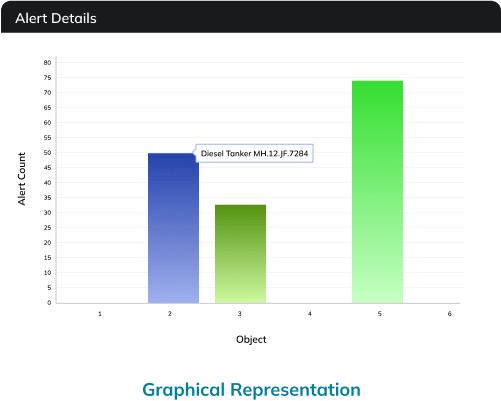

Instant Alerts: If the tire’s pressure drops below or rises above the safe threshold, an alert is triggered and sent to both the driver and the fleet manager.

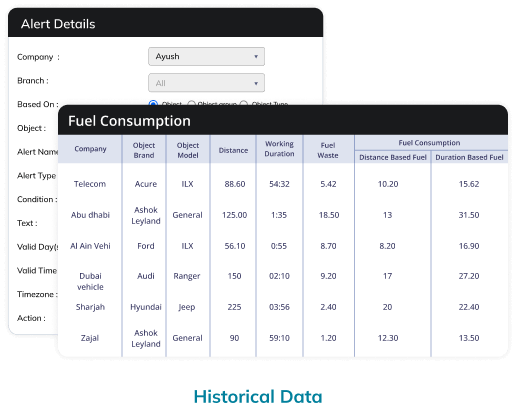

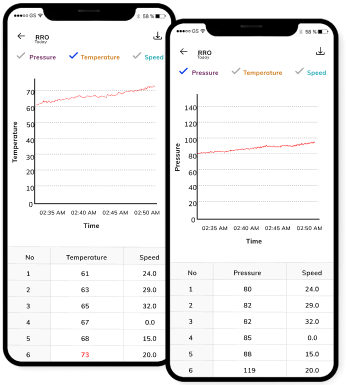

Reports and Charts: The software generated reports on tire pressure and performance, allowing companies to identify patterns and trends that could indicate issues with their vehicles or routes.

This data helped to optimize fleet operations, reducing fuel consumption and maintenance costs.

Results

Ensure Safety: Ensure safe transportation of hazardous chemicals by monitoring tire pressure in real time.

Optimized Operations: The valuable data generated by the software helped companies optimize their fleet operations, improving safety and reducing costs.