Mining companies use heavy equipment such as pickup trucks and forklifts to move materials across steep terrain. The tires on these vehicles are exposed to extreme conditions such as sharp rocks, uneven terrain and heavy loads. Ensuring that these tires are properly inflated is essential for maintaining vehicle performance, reducing downtime, and preventing accidents.

Introduction

Challenges

Tire-Related Incidents: Tires are exposed to extreme conditions in a harsh mining environment, including rough terrain, heavy loads and grinding equipment. Tire failures can lead to vehicle accidents, costly downtime, and maintenance expenses.

Safety Concerns: Tire blowouts or sudden pressure losses in large mining vehicles can pose significant safety risks to both operators and the surrounding workforce.

Operational Efficiency: Downtime due to tire-related incidents or unscheduled maintenance can disrupt mining operations, leading to production losses and increased costs.

Manual Inspection: Monitoring tire pressure in a large fleet of vehicles was time-consuming and costly, as it typically involved manual inspections. This was especially challenging in remote mining sites where access to vehicles was limited.

Challenges

Solution

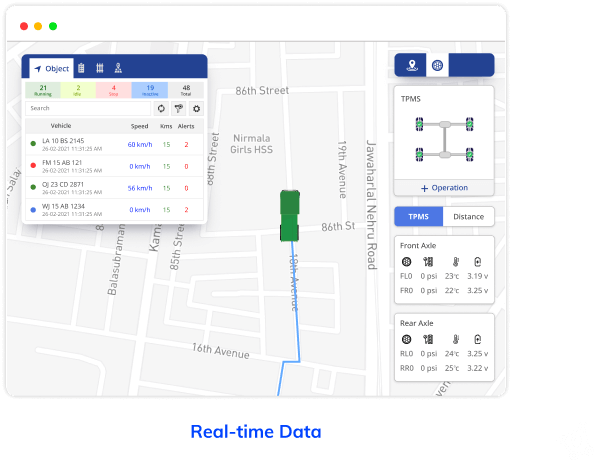

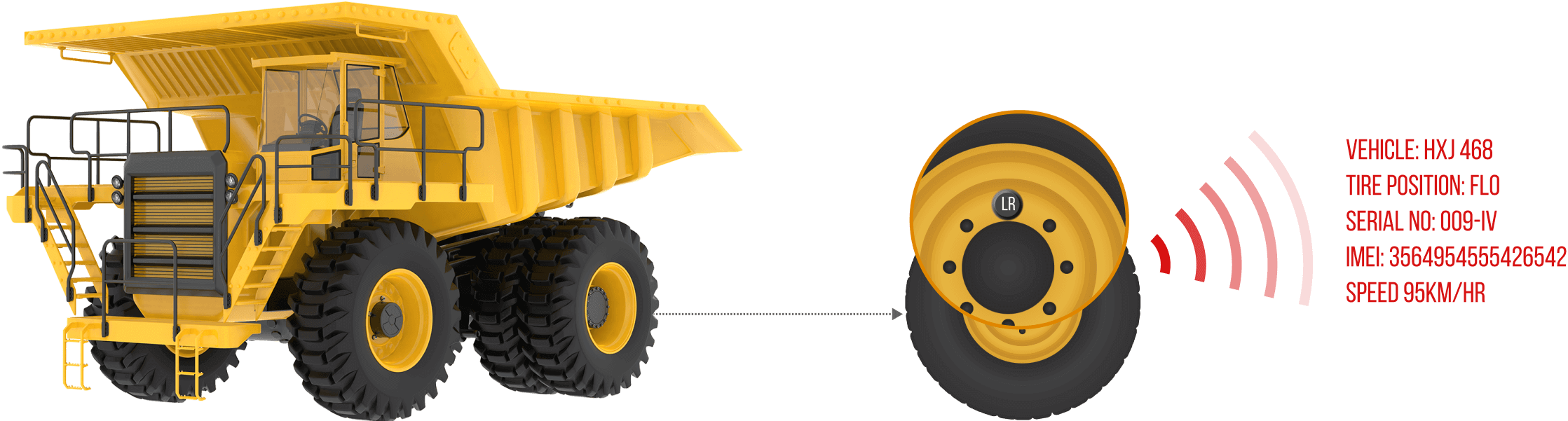

TPMS Sensors: TPMS sensors are installed on each tire of the mining fleet’s heavy equipment for continuously monitoring tire pressure and temperature.

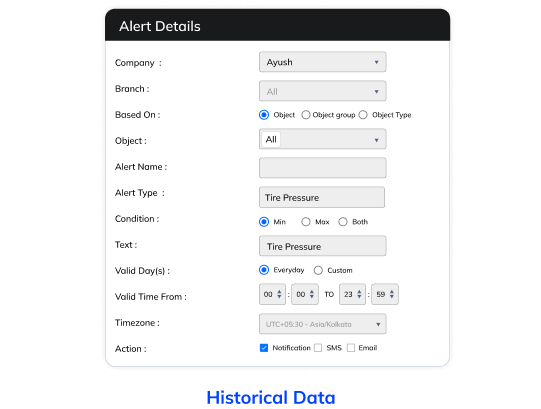

Instant Alerts: If anytime tire’s pressure drops below a safe threshold, an alert is triggered and sent to operators, maintenance teams, and fleet managers.

Reports and Charts: The TPMS software offers comprehensive reports and charts allowing for in-depth analysis of tire performance data. Fleet managers can analyze historical data, visualize trends, and make data-driven decisions about tire maintenance and operations.

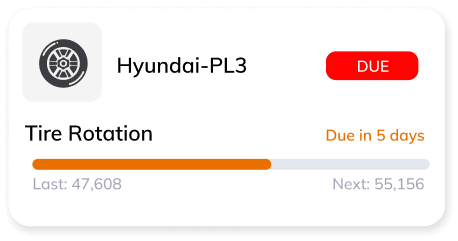

Scheduled Maintenance: Over time, the TPMS system collects data on tire wear and performance. Fleet Managers use this data for predictive maintenance, scheduling tire rotations or replacements before issues become critical.

Results

Maintain Optimal Pressure: Mining companies can maintain optimal tire pressure and reduce the risk of accidents and downtime.

Quick Actions: The real-time monitoring provided by our software can be used by operators to identify potential problems, allowing them to take corrective action before a serious issue occurs.