Construction fleets, including vehicles and equipment, are essential for the construction industry. To ensure that these fleets are operating safely and efficiently, it is necessary to maintain them regularly. Maintenance needs include tasks such as oil changes, filter replacements, inspections, and repairs. Failure to perform regular maintenance tasks can lead to unexpected breakdowns, increased downtime, and even accidents.

Introduction

Challenges

Maintenance Neglect: Construction equipment and vehicles are subjected to heavy usage and harsh environments, leading to accelerated wear and tear. Without fleet reminder software, it’s challenging to track and schedule maintenance accurately, resulting in neglected servicing and potential breakdowns.

Safety Risks: Safety is important in construction. Without proper reminders, safety inspections, operator certifications, and equipment checks may be overlooked, increasing the risk of accidents and injuries.

Compliance Issues: Construction fleets must adhere to various regulatory requirements, including emissions standards, safety inspections, and operator certifications. The absence of reminders can lead to non-compliance, resulting in legal penalties and operational disruptions.

Operational Inefficiency: Inefficient maintenance and repair processes can lead to excessive downtime, increased repair costs, and delayed project timelines, negatively impacting productivity and profitability.

Challenges

Solution

To address the challenges faced by the construction company we provide them with fleet reminder solution.

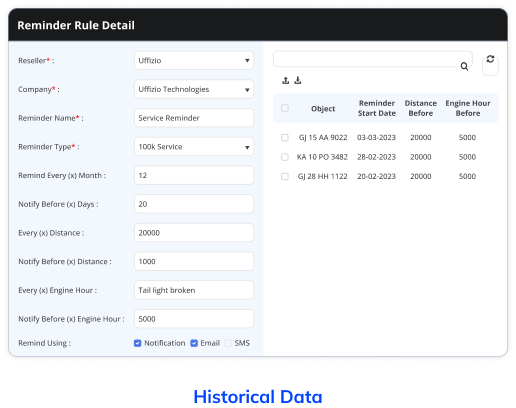

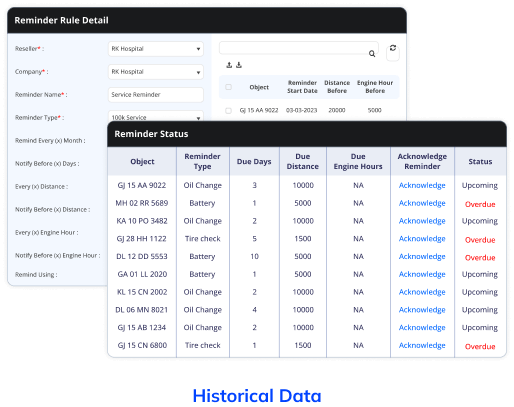

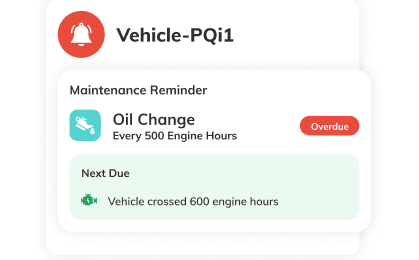

Schedule Maintenance: Schedule routine maintenance tasks based on usage, mileage, or engine hours. It sends alerts to fleet managers and technicians when maintenance is due, ensuring timely servicing.

Compliance Monitoring: Fleet reminders are set up for emissions testing, operator certification renewals, and other regulatory requirements. This ensures that the fleet remains compliant with regulations, avoiding fines and legal issues.

Insightful Reports: The software allows users to customize reminder reports based on specific criteria, such as vehicle type, location, or maintenance priority, tailoring the information to their unique needs.

Store and maintain a comprehensive maintenance history log within the software for tracking completed tasks and identifying maintenance trends.

Results

Incorporating maintenance reminder the construction company saw significant changes.

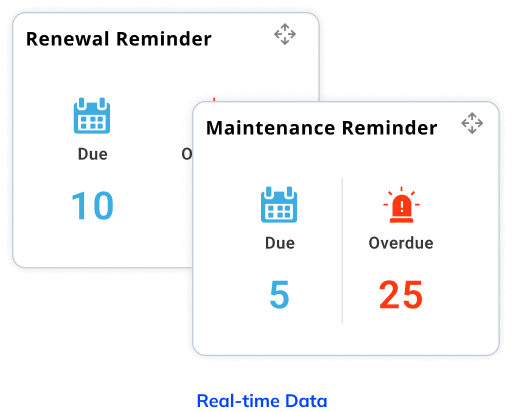

Reduced Vehicle Downtime: They reduced downtime and increased productivity by ensuring that maintenance tasks are completed on time, and vehicles and equipment are always in good condition.

Improved Safety: They improved safety and reduced the risk of accidents by identifying potential issues before they occur and proactively addressing them.