Safe and effective distribution of pharmaceutical products is critical to ensure patient safety and well-being. Temperature is an essential component of this process, as many medications and vaccines require strict temperature controls to maintain their efficacy. In this use case, we will explore how temperature monitoring is used in pharma product distribution, as well as the challenges and solutions associated with this process.

Introduction

Challenges

Temperature Fluctuations: The temperature-sensitive products are highly susceptible to temperature fluctuations, which can occur due to various factors such as weather conditions, handling, storage, and transportation.

Regulatory Compliance: The pharmaceutical company needs to comply with various regulatory bodies that mandate strict guidelines for maintaining the temperature range during the transport of pharmaceutical products.

Limited Visibility: The company has limited visibility into the temperature conditions inside the transport vehicles during the transportation, making it challenging to identify and rectify temperature excursions in real-time.

Challenges

Solution

To address these challenges the company adopt our temperature monitoring software

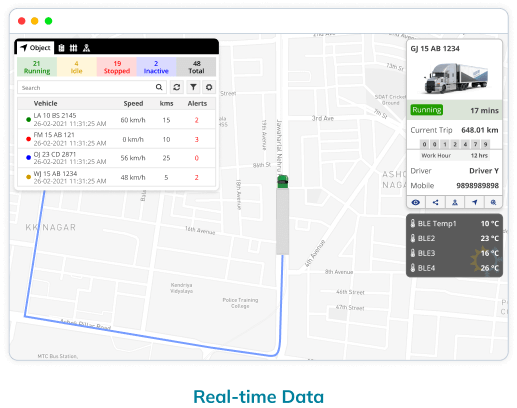

Real-time temperature monitoring: Implementing real-time temperature monitoring systems ensured that the temperature is being constantly monitored and that any temperature deviations are detected and addressed immediately.

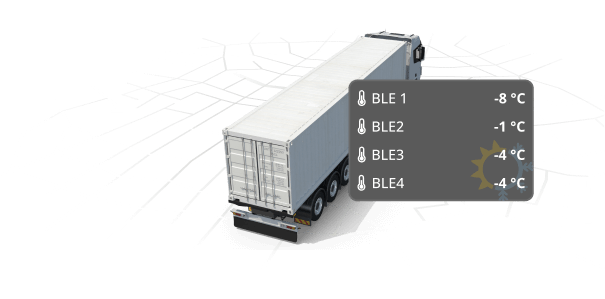

This was done using temperature sensors that can be placed inside the containers used for transportation or storage.

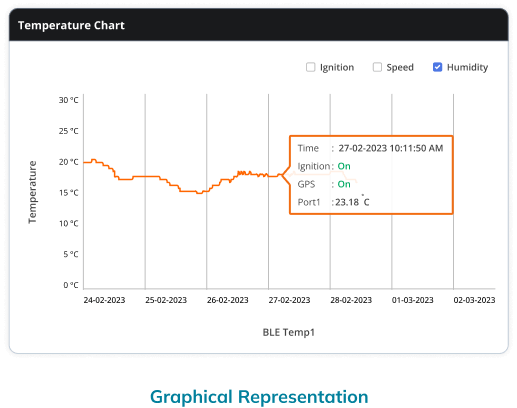

Data logging and reporting: The temperature monitoring system provids real-time data on temperature fluctuations during transportation and storage. This helps to identify trends or patterns in temperature deviations and helped take proactive measures to prevent them.

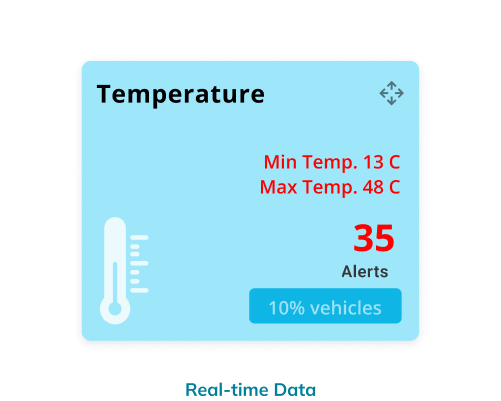

Automated Alerting System: The solution is equipped with an automated alerting system that sends instant alerts to the logistics team if the temperature deviates from the desired range.

Results

Ensuring Product Quality: Temperature monitoring helped maintain the quality and efficacy of pharmaceutical products by ensuring that they are stored and transported within the required temperature range.

Cost Savings: Temperature monitoring software helped prevent product damage, which resulted in significant cost savings for a pharma company.

Improved Patient Safety: Ensuring that medications and vaccines are stored and transported under the required temperature conditions helped improve patient safety by reducing the risk of ineffective treatments or adverse reactions.